EMERGING FROM TURKEY, THE HEART OF THE GLOBAL CEMENT INDUSTRY, CTN GROUP HAS DEVELOPED LOCAL TECHNOLOGY THAT RECYCLES FLUE GAS, AND IS EAGER TO REPLACE THE 95% CHINESE DOMINANCE IN THE GLOBAL MARKET

By HUSNIYE GUNGOR

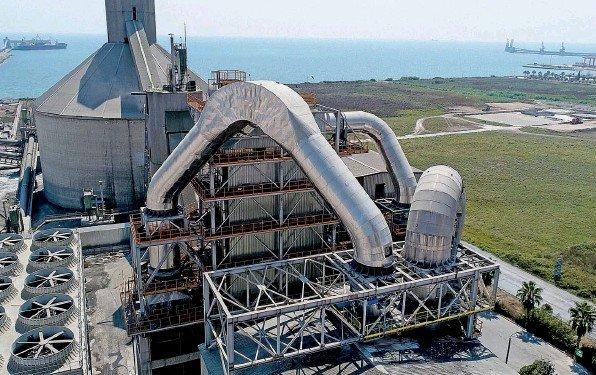

TURKEY is one of the biggest players in the global cement industry, with 62 factories and a million tonnes of clinker capacity per year. The sector’s value-added contribution to the economy includes an export surplus of 25m tonnes per year. However, it is also under pressure to secure investments related to the environment. Today, a small and medium enterprise, CTN Group, founded in Adana in 2010 is transforming cement factories into more environmentally-friendly facilities that generate their own electricity from the waste gas spewing out of their chimneys, not only in Turkey, but around the world. General Manager Ozkan Cetin says that their technology will replace the 95% dominance of the Chinese companies in the global market.

One of the key investment items in the sector, which has evolved toward more environmentally-friendly cement factories with new technologies, is systems for the recycling of flue gases. CTN Makine, researching new technologies with the R&D and Design Center certificate it received in 2017, pursued a significant transformation in the cement industry with its patented ORC (Organic Rankine Cycle) system.

A strong alternative for the dominant Chinese technology, both in Turkey and the world, the system has a 65% localization rate.

Only 12 of the 62 cement factories in Turkey recycle its exhaust gas, 10 of which are Chinese companies, according to Ozkan Cetin, CTN Group General Manager. “We have done only two until know. So the domestic market potential is there. However, we have more aggressive plans to be a global player,” he says. With Portugal already an export destination for its technology, CTN Group is on the verge of getting a EUR 9.6m job in Saudi Arabia, for which the results of the tender will be concluded this week. With Biden government taking the administration in the U.S., the American market also offers big opportunities for the company. Cetin says that they have been in talks to enter the U.S. market for the last four months. It may take some time, since they want to make a strong entrance into the market.

Steps toward globalization are nothing new for CTN Group. The company partnered with an Italian company in 2017, using funding it received from the Credit Guarantee Fund. There months ago it increased its 60% share in Italian CTP Team to full ownership. Cetin, the 44-year-old boss of CTN Makine, told his story of creating the ORC technology, which emerged in Adana, reaching global markets through Milan.

“Filtering systems in cement plants are monopolized by Chinese companies in Turkey,” he says. “They are setting up this system for the entire industry in order to enable them to generate electricity from flue gas. However, in doing so, they use groundwater to cool the gas. This bothered me a lot. My path crossed with my client of that time [CTP Team] in Milan while I was researching how to find an alternative way.” CTN Group then started to develop a technology with its Italian partner after investing in R&D and today holds the patent of the ORC technology that generates electricity using organic methods.

USD 2M INVESTMENT IN R&D

CTN Group exports 70% of its production. Most of its clients are in Europe, such as CTP, one of the most important companies in the sector in Italy which later partnered with CTN Makine in 2017. “CTP Team wanted to sell shares after the financial crisis. Initially, I became a partner in the company with 60% share. Then in September last year, we bought sole ownership of the company. They already had studies on organic transformation technologies, but they stopped working on it for some reason,” Ozkan says.

“I was obsessed with this idea. We received consultancy from many experts and made an investment of USD 2m. European and Turkish engineers worked together and created a new system in ORC technology.”

The ORC technology converts flue gas into electricity using oil instead of groundwater. “The daily groundwater consumption of 10 factories using Chinese technology is approximately 17,000 cubic meters. This is equivalent to the monthly water consumption of 1,335 families,” Ozkan notes. “Groundwater is very precious. An alternative technology was possible, especially in a time while the world is facing the threat of drought in the foreseeable future.” 25 percent more efficient

With the ORC (Organic Rankine Cycle) technology, the gas exiting the chimney of the cement factory with a temperature of approximately 400 degrees is cooled down to 120 degrees. This heat is also used for hot water supply and drying processes.

The ORC technology applied by CTN Group is more expensive than the groundwater system used by the Chinese, according to Ozkan. “However, the calculations have revealed that it is 25% more efficient and that the cost gap is closed in five years,” he says.

The first client of this domestic technology was Sanko Cimento, the cement business line of Sanko Group. Cetin says that they established a zero waste-focused facility with a USD 10m tender they won.

Then Sonmez Cimento followed. “They invested USD 15m for Europe’s largest cement plant established with ORC technology. It is an 8.5 megawatt facility that enables the factory to generate 35% of the its annual energy from its own flue gas. We have used the local contribution well. Our new client from Portugal paid a visit to Yumurtalik, Adana to examine the factory.”

CTN Group has evolved from a subcontractor to a company that develops its own designs in a decade. The ORC system will be used in three more cement factories to be established in Turkey in 2021. The first is a French company; the second is the Italian group Cementir, the owner of Cimentas in Turkey, and the third is As Cimento from Burdur.

“We held meetings with them. None of them have invited Chinese companies to their tenders. There is now an awareness in the sector about groundwater,” he says.

FIRST EXPORT TO PORTUGAL

The first export of ORC technology from the CTN Group will be to Portugal. Cetin states that they made an agreement with Secil Group, one of Portugal’s leading companies, “We participated in the tender with the ORC system. Chinese companies were not even invited to the tender. Therefore, we were able achieve a cost advantage compared to our European competitors, which do not have the experience we have. The tender in Portugal is worth EUR 14.5m. This will be the first ORC export from Turkey to Europe,” he said.

ONLY TURKISH COMPANY IN ‘KILOMETRO ROSSO’ OF MILAN

CTN Group has a facility equipped with industry 4.0 and manufacturing entirely with robotic applications in the Adana Organized Industrial Zone. Established in a 11,000 square-meter area, the facility employs 96 people. With the acquisition of CTP Team in September 2020, the company is now headquartered at ‘Kilometro Rosso’, a leading innovation hub in Europe established in Bergamo, Milan, alongside the MilanVenice expressway. “Our headquarter at Kilometro Rosso in Italy is the touch point for our worldwide projects,” says Ozkan Cetin, CTN Group General Manager. CTP Team, is an international engineering and manufacturing company with 50 years of experience in the sector of environmental protection systems and heat recovery. The acquisition made CTN Group, the parent company of CTP Team, the only company in Kilometro Rosso.